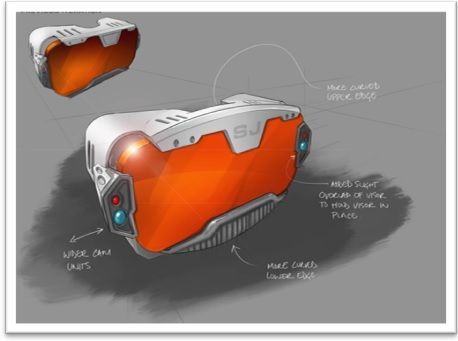

Product Design

What we do.....

Toolcast generate product design solutions that meet the requirements of real people. We work in an environment in which rigorous thinking generates creative, commercially viable solutions. Plastic Injection moulded parts are optimised for productivity.

One of our Engineers will visit your site to analyse your project requirements and help to fulfill the project brief. 20 years of tooling and moulding experience assists in the reduction of development lead-times and the overall schedule to production launch.

As standard we sign a non-disclosure agreement before entering into detailed discussions to ensure your intellectual property is correctly protected

3D & 2D cad data files are created using SolidWorks and can be output in a format of your choice.

How it works

-

1. Send a request

Send us an e-mail or call to speak to one of our Engineers.

-

2. Discuss the brief

We will walk you through the process and discuss your requirements.

-

3. Approve budget

You will normally receive our quotation withon 48 hours. On receipt of an order our Enginners will begin the Design process.

-

4. Start project

Depending on your requirements, a number of designs are submittied for approval before finalising the chosen design.

-

5. Finish on schedule

Cad data, 2d drawings and models will be completed within the agreed schedule.

Follow us

Privacy & Cookie Policy

Terms & Conditions